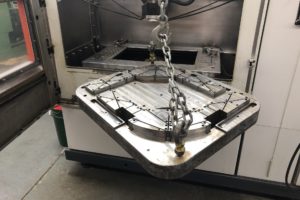

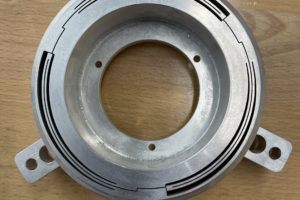

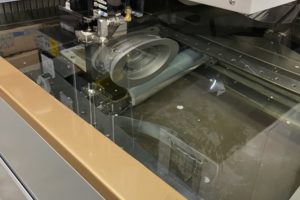

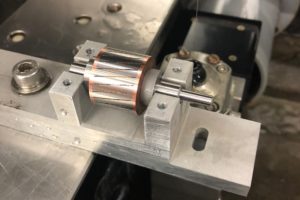

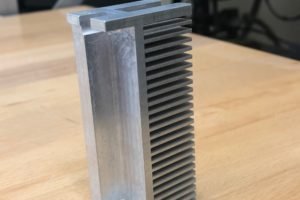

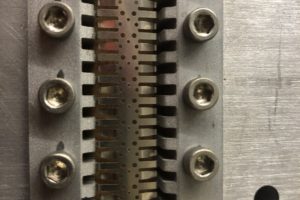

Our advanced Wire EDM machines can precisely cut contours on both large and miniature sized components. We can machine internal features and radii measuring as small as .002”, with surface finishes as low as 8 RMS with little to no recast. Wire Pro is capable of fine wire EDMing, using wire diameters as small as .004″. Our sophisticated, 4-axis Wire EDM equipment can cut complex contours with different shapes on either end of the part.

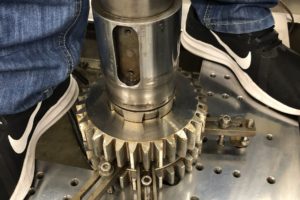

Specializing in the manufacturing of aerospace components, medical devices, surgical tools, and military components, our Wire EDM technology produces precise parts that meets our clients’ requirements for superior accuracy and on time delivery. Utilizing the latest CAD/CAM software gives Wire Pro the ability to rapidly create programs and turn them into parts, saving our client’s time and money.

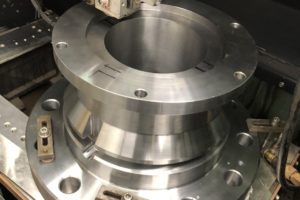

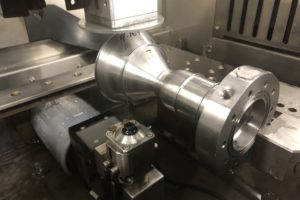

Possessing a large taper cutting capacity, our Wire EDM technology allows us to form more intricate contours out of difficult to machine metal materials, such as stainless steel, tool steel, high temperature alloys, stainless alloys, and titanium. All of our ISO compliant Wire EDM services meet high industry standards and client expectations. Contact Wire Pro today to learn more about our advanced Wire EDM capabilities.